Problem Definition

CNC metal machining industries face significant challenges in process and quality control due to factors such as tool wear, material inconsistencies, and the need to maintain tight tolerances for precision. Detecting micro-defects, surface imperfections, and dimensional inaccuracies is often complex and requires careful monitoring. Environmental factors like temperature fluctuations and machine vibrations can further impact machining accuracy, making consistent quality control a demanding task.

What we offer

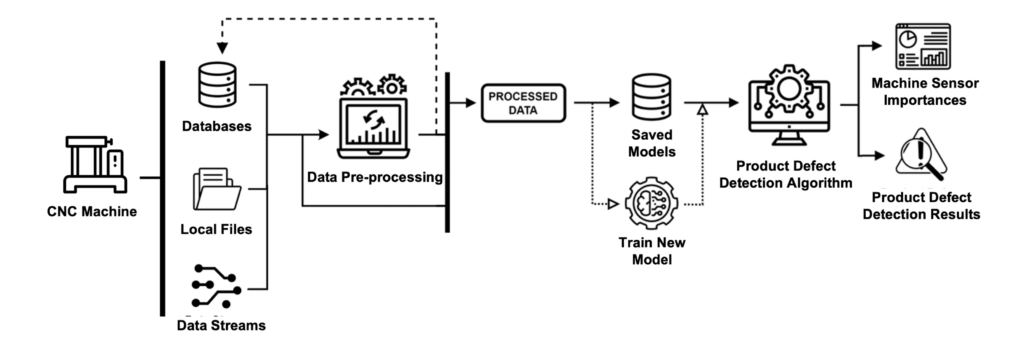

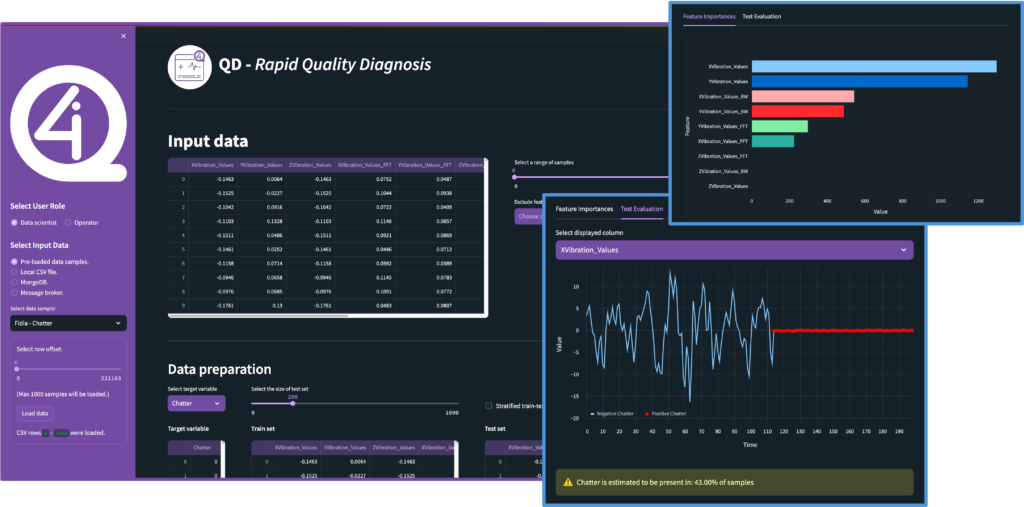

MetAlert offers a comprehensive solution designed to enhance manufacturing efficiency and quality by leveraging advanced technologies. It tracks and analyzes industrial sensor signals installed in machinery, using machine learning algorithms to detect defective products and rapidly diagnose problematic manufacturing process conditions. By delivering valuable insights into manufacturing lines through intuitive visualizations and XAI techniques, it aims to assist operators to make effective data-driven decisions.

The benefits provided by the MetAlert solution to metal machining industries include:

- Real-time industrial sensor data monitoring.

- Product defect detection using advanced machine learning algorithms.

- Rapid diagnosis of problematic manufacturing process conditions, such as CNC machine chatter.

- Provision of sensor importances through XAI techniques to support informed decision-making.

- Data visualization to facilitate the presentation and understanding of analytics results.

Impact

MetAlert has a positive impact in at least 3 areas of the UN’s Sustainable Development Goals which can be translated to positive ESG metrics for the companies that use our solution.